Pel-Dar

Polymers Ltd

Polymers Ltd

פל-דר פולימרים הינה חברת כימיקלים בבעלות פרטית המתמחה בשיווק והפצה של כימיקלים למגזר התעשייתי עם דגש על תעשיות המזון, כימיה, פרמבצטיקה וכו'.

פל-דר פולימרים רואה עצמה כחברה המעניקה פיתרון כולל למגוון לקוחותיה וצרכיהם וזאת ע"י שילוב ייחודי בין יכולות שיווק, ידע טכנולוגי וניסיון עשיר, ניסיון רב שנים, שירות, יישום ואיכות.

בפל-דר פולימרים אנו נדע כיצד להתאים ו/או לפתח את מוצרינו בהתאם לדרישות הלקוח וצרכי השוק המשתנים.

פל-דר פולימרים רואה עצמה כחברה המעניקה פיתרון כולל למגוון לקוחותיה וצרכיהם וזאת ע"י שילוב ייחודי בין יכולות שיווק, ידע טכנולוגי וניסיון עשיר, ניסיון רב שנים, שירות, יישום ואיכות.

בפל-דר פולימרים אנו נדע כיצד להתאים ו/או לפתח את מוצרינו בהתאם לדרישות הלקוח וצרכי השוק המשתנים.

Call now 972-50-9669929** חייג עכשיו: 050-9669929

POB 148

Yokneam 2069203

Tel: 972-50-9669929

פקס: 04-9935546

אי-מייל: mail@pdpolymers.co.il

Yokneam 2069203

Tel: 972-50-9669929

פקס: 04-9935546

אי-מייל: mail@pdpolymers.co.il

Envelope and Belt Lubricants:

Used tires are one of the biggest environment hazards that exist on our planet. The rubber compound of tires consists of high resistance chemicals that cause the used tire to last and not to break down. In the past, there were many ways to get read of used tires, one of the main methods were to bury them in the ground and build over them even entire cities in some cases. It was quickly understood that the used tires were releasing toxic gases to the ground which were seeping into underground reservoirs and by that contaminating drinking water.

Tire industry became desperate for a solution to this problem. In the early 1900 a solution was found, recycling or, now days retreading, has become a great option to minimize the harm to nature. The retread process is very simple, once a tire has finished its life cycle it travels to the retread factory where it is named by casing instead of tire. The casing gets inspected, buffered and renewed. Once the whole process is over the used tire gets back on the road instead of to waste. Material cost for a retreaded tire is about 20% that of making a new tire.

There are two main processes used for retreading tires, called Mold Cure and Pre Cure. Both processes start with the inspection of the tire, followed by inspection method such as shearograph in order to locate non-visible damage and embedded debris and nails. Some casings are repaired and some are discarded. Tires can be retreaded multiple times if the casing is in usable condition. Commercial vehicles tires can last up to 600,000 miles if they're retreaded two to three times.

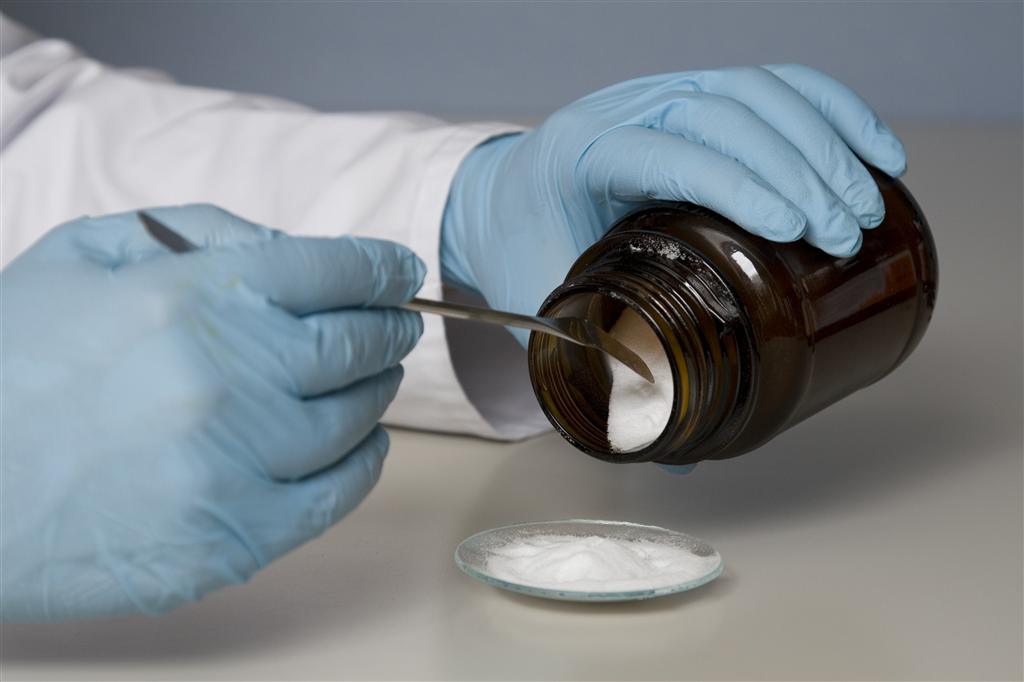

The curing of the retreaded tire takes place in an Autoclave. The tires are placed in it in what would be "envelopes" the envelope is wrapped around the retreaded tire. Then, it is sealed vacuumed tight. Before placing the tire in the envelope it is necessary to place a lubricant, the lubricant ensures that the tire does not stick to the envelope during the curing process in the Autoclave and can be reused.

The Pelmar Engineering Group Ltd is the exclusive distributor of CRS Lubricants worldwide, excluding North America.

Product Portfolio:

CRS Envelope Lube:

This product is new technology and is one of the best grade silicone emulsion availalbe in the market today. It is superior to other products as It can be diluted it with 8 parts water and still get excellent results. Cost-Savings are substantil and will allow your business to grow with stable supply and consistent quality of Envelope lubricants.

CRS Belt Lube:

Belt Lube is a high grade, high percentage pure silicone emulsion. It aids in centering tire on hub as well which improves quality. It will condition the belt without causing it to stretch or sag. Once it is applied on the hub, it could be used for multiple times, up to 30 tires and even more!

Contact Us To Learn More